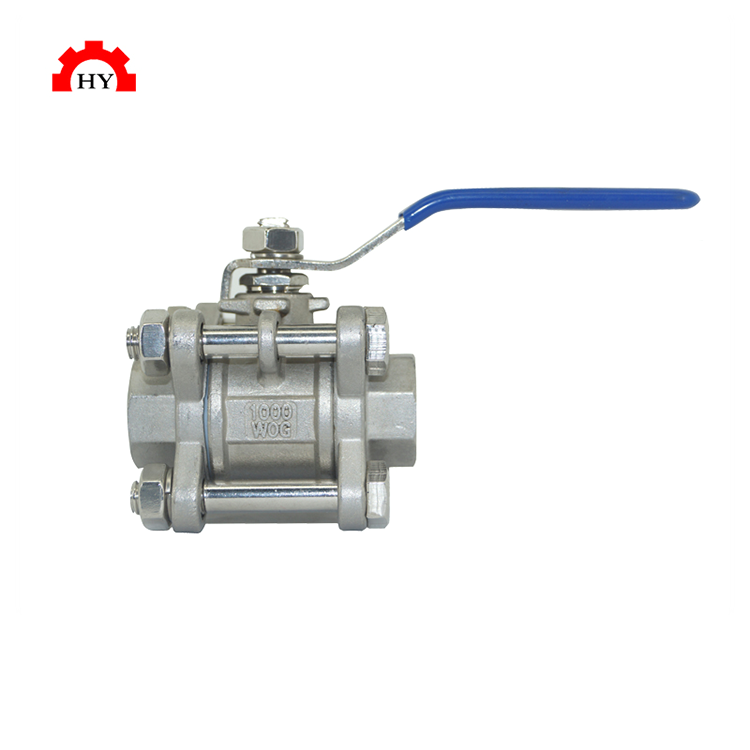

Maintenance and care guide for China female threaded ball valves

China female threaded ball valves are widely used in various industrial applications to control the flow of fluids. These valves are known for their reliability, durability, and ease of operation. However, like any mechanical component, they require proper maintenance and care to ensure optimal performance and longevity. This guide provides comprehensive instructions for maintaining and caring for China female threaded ball valves, ensuring their smooth operation and preventing potential issues.

Regular Inspection:

Regular inspection is crucial for identifying potential problems early on and preventing severe valve failures. Here are the key areas to inspect:

1. Valve Body: Inspect the valve body for signs of corrosion, cracks, or leaks. Check for any physical damage that may have occurred during installation or operation.

2. Packing Gland: Examine the packing gland for signs of wear or damage. Ensure that the packing is tight enough to prevent leaks but not too tight, as this can cause excessive friction and impede valve operation.

3. Valve Seat: Inspect the valve seat for any signs of damage, pitting, or erosion. A damaged valve seat can lead to leaks and compromise valve performance.

4. Ball: Check the ball for signs of wear, pitting, or scratches. A damaged ball can cause leaks and reduce valve efficiency.

5. Valve Stem: Inspect the valve stem for signs of bending, corrosion, or damage. A damaged valve stem can affect valve operation and lead to leaks.

Maintenance Procedures:

1. Cleaning: Regularly clean the valve body and components to remove dirt, debris, and other contaminants. Use a soft cloth or brush and mild detergent to avoid damaging the valve’s surface.

2. Lubrication: Apply suitable lubricant to the valve stem, packing gland, and other moving parts according to the manufacturer’s recommendations. Lubrication reduces friction, prevents wear, and ensures smooth valve operation.

3. Packing Adjustment: If the packing gland is leaking, it may need adjustment. Carefully tighten the packing gland nuts until the leak stops, but avoid overtightening, as this can cause excessive friction and impede valve operation.

4. Valve Seat Repair: If the valve seat is damaged, it may need to be repaired or replaced. This is a specialized task that should be performed by qualified personnel.

5. Ball Replacement: If the ball is damaged or worn, it may need to be replaced. This is also a specialized task that requires careful attention to detail.

Preventive Maintenance:

In addition to regular maintenance, there are several preventive measures that can help extend the life of China female threaded ball valves:

1. Proper Installation: Ensure that the valve is properly installed according to the manufacturer’s instructions. Incorrect installation can lead to premature failure and leaks.

2. Flow Control: Avoid excessive flow rates and pressure surges through the valve. Operating the valve within its specified flow and pressure limits helps prevent damage and ensures reliable performance.

3. Temperature Control: Ensure that the valve is used within its specified temperature range. Exceeding the temperature limits can cause damage to the valve’s components and compromise its functionality.

4. Corrosion Protection: If the valve is exposed to corrosive environments, consider using corrosion-resistant materials or applying protective coatings to prevent corrosion.

Troubleshooting Common Issues:

1. Valve Leaking: Leaking can occur due to worn packing, damaged valve seats, or a damaged ball. Check these components and repair or replace them as necessary.

2. Valve Sticking: Sticking can occur due to insufficient lubrication, dirt accumulation, or corrosion. Clean and lubricate the valve, and address any underlying issues causing the sticking.

3. Valve Not Opening or Closing Properly: This can occur due to a damaged valve stem, a jammed ball, or a damaged valve seat. Inspect these components and repair or replace them as necessary.

4. Valve Chatter: Chattering occurs when the valve rapidly opens and closes, causing noise and vibration. This can be caused by excessive flow rates or pressure surges. Adjust the flow rate and pressure to within the valve’s specified limits.

Conclusion:

By following the maintenance and care instructions outlined in this guide, you can ensure that China female threaded ball valves operate smoothly and reliably, extending their lifespan and reducing the risk of costly failures. Regular inspection, proper maintenance, and preventive measures can help you avoid potential problems and keep your valves functioning optimally.