What is 3pc female thread ball valve?

A 3-piece female threaded ball valve is a type of ball valve designed with three main components or pieces that can be easily disassembled for maintenance or repair. The term “female threaded” refers to the type of connections on the valve, which typically have female threads that allow it to be connected to pipes or other fittings with male threads. Here’s a breakdown of the key features:

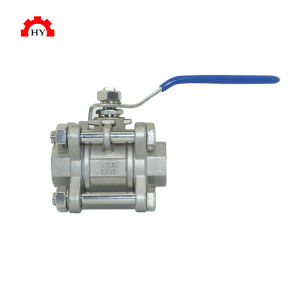

3-Piece Design:

The valve is constructed in three separate pieces—two end caps or connectors and a center section that contains the ball and the valve mechanism. This design allows for easy disassembly for cleaning, maintenance, or replacement of components.

Female Threaded Connections:

The valve has female threads on both ends, allowing it to be directly screwed onto pipes or other fittings with male threads. This threaded connection provides a secure and leak-resistant joint.

Ball Valve Mechanism:

The valve uses a ball with a hole (bore) through its center as the flow control mechanism. When the valve is open, the ball allows fluid to flow through the bore. When closed, the ball is rotated to block the flow.

Handle or Actuator:

Typically, a handle or actuator is attached to the ball to control the valve’s position. Turning the handle or actuator rotates the ball, allowing the user to open or close the valve.

Material of Construction:

These valves can be made from various materials, including stainless steel, brass, or other alloys, depending on the application and the type of fluids or gases they will be handling.

Applications:

3-piece female threaded ball valves are commonly used in a variety of industries and applications where a reliable and easily maintainable shut-off valve is required. They are suitable for controlling the flow of liquids and gases in pipelines.

Versatility:

The 3-piece design and threaded connections make these valves versatile for different installation and maintenance scenarios. They are often preferred in situations where frequent maintenance or cleaning is necessary.

Sizes and Pressure Ratings:

These valves come in various sizes to accommodate different pipe diameters, and they are designed to handle specific pressure ratings depending on the material and construction.

These valves are popular in industrial, commercial, and residential settings where precise control of fluid or gas flow is required, and where the ability to disassemble the valve for maintenance is advantageous. The choice of material and specifications would depend on the specific requirements of the application.